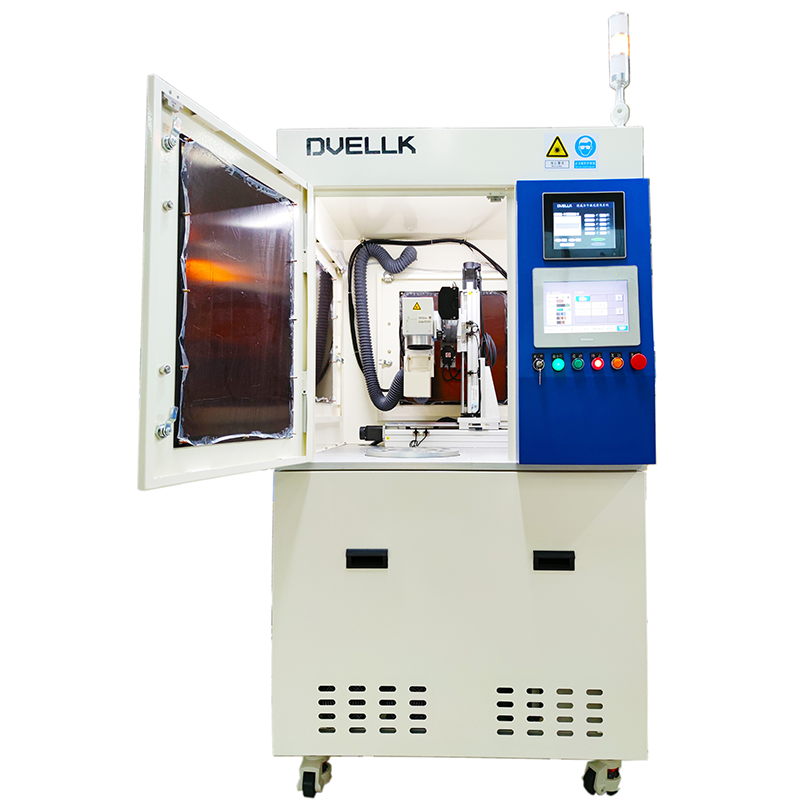

LASER ADHESIVE REMOVAL WORKSTATION

CL-S500MW

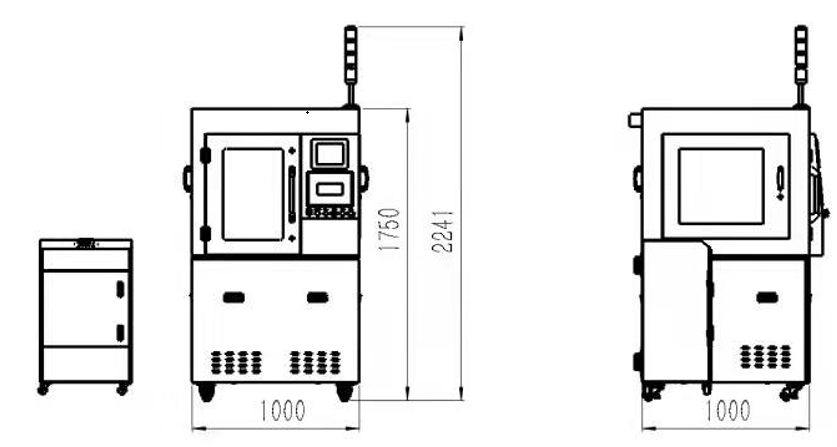

Parameters:

| Model No. | CL-S500MW | Description | laser cleaning machine |

| Average Power | 500 watts | Operating Voltage | 110~240 V / 50 HZ |

| Laser Type | mopa | Cooling Method | wind |

| Control Sys. | RAYSEE / DVELLK | Wave Length | 1064 nm |

| Beam Pattern | two-dimensional | Scanning Graphics | 5 or above |

| Beam Length | 10 cm | Beam Width | 2 cm |

| Focal Length | 160mm/254mm/330mm | Working Temperature | 0℃~45℃ |

| Cable Length | 5 m | Fiber Length | 5 m |

| Working Humidity | 10%~95% | Certificate | CE / FDA / ISO9001 |

Overall View:

Features:

◇ Advanced Laser Technology: This workstation employs cutting-edge laser technology to precisely ablate or vaporize adhesive residues, leaving the underlying material unharmed.

◇ Non-Destructive: Laser-based adhesive removal ensures that the base material’s integrity remains intact, preventing damage during the process.

◇ Efficiency and Speed: Laser technology offers an efficient and considerably faster alternative to traditional adhesive removal methods, reducing downtime and increasing productivity.

◇ Environmentally Friendly: Laser-based adhesive removal generates no hazardous waste or harmful emissions, making it an eco-friendly solution.

◇ High Precision Control: The system allows operators to fine-tune laser parameters, providing precise control over the adhesive removal process for different materials and adhesive types.

◇ User-Friendly Interface: The workstation typically features a user-friendly interface for easy operation, monitoring, and adjustment of settings.

◇ Safety Measures: Incorporates laser safety features, including interlocks and protective shielding, to ensure the safety of operators and bystanders.

◇ Versatile Applications: It can be used to remove adhesives from a wide range of materials, including metals, plastics, ceramics, and more.

◇ Minimal Maintenance: Laser systems typically have lower maintenance requirements compared to traditional adhesive removal techniques.

◇ Consistent Quality: Laser adhesive removal delivers consistent, high-quality results, ensuring a clean and residue-free surface.

After-Sales Services:

◇ Technical Support: Our team of experienced technicians is available to assist you with any technical issues or questions you may have. Whether it’s troubleshooting, maintenance guidance, or software updates, we’re here to help.

◇ Free Training: We offer training programs to ensure that your personnel are well-versed in operating and maintaining the equipment safely and efficiently. This empowers your team to maximize the benefits of our laser cleaning solutions.

◇ Spare Parts and Consumables: We maintain a ready supply of genuine spare parts and consumables to minimize downtime. Our efficient logistics ensure prompt delivery of required components.

◇ Warranty Coverage: Our laser cleaning equipment comes with a comprehensive warranty, providing you with peace of mind. If any issues arise during the warranty period, we will promptly address them at no additional cost.

◇ Customized Service Plans: We understand that every customer has unique needs. That’s why we offer customized service plans tailored to your specific requirements. Whether it’s regular maintenance or extended warranties, we have you covered.

◇ Remote Assistance: In many cases, we can diagnose and resolve issues remotely, saving you time and reducing operational disruptions.

◇ On-Site Support: For more complex problems, we offer on-site support to ensure your equipment is up and running as quickly as possible.

-

Previous:

LASER OXIDE REMOVAL WORKSTATION

Next: 3000 WATTS CART LASER CLEANER